Boost efficiency, reduce product damage, and ensure seamless deliveries with smart Product Packaging in SAS Inventory.

Learn how to manage Product Packaging in SAS Inventory with this 2025 guide. Create packages, configure package types, and streamline your logistics process today.

Product Packaging in SAS Inventory

What Is Product Packaging in SAS Inventory?

Product Packaging in SAS Inventory allows users to manage how goods are grouped, stored, and transported. With the right packaging setup, businesses can:

- Protect products from damage.

- Streamline logistics.

- Track packaged goods during stock movements.

- Enhance operational efficiency.

This functionality is vital for maintaining product quality and ensuring customer satisfaction.

How to Enable Product Packaging Features

To begin using Product Packaging in SAS Inventory, follow these steps:

- Navigate to the Settings menu.

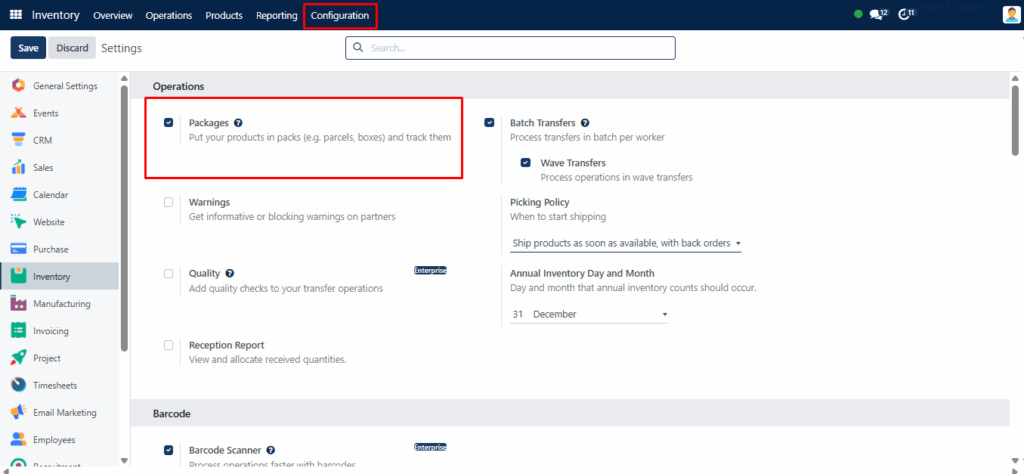

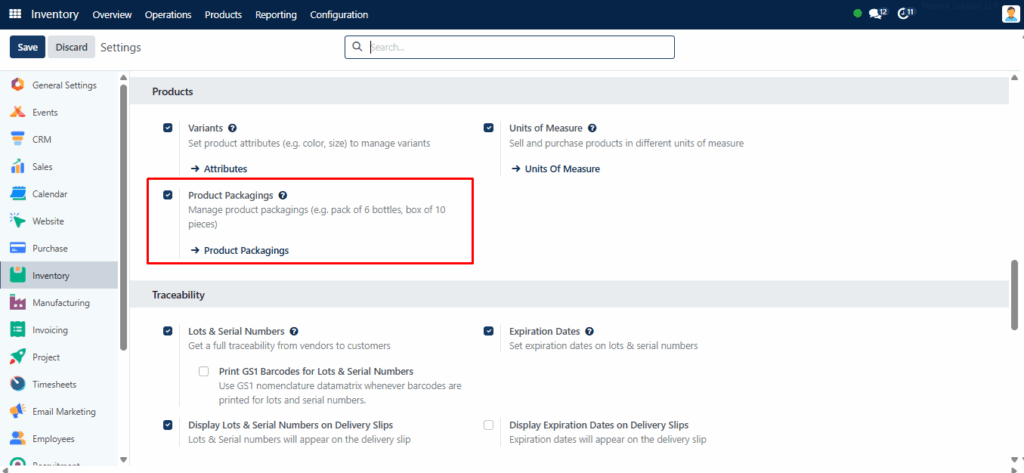

- Enable the following under relevant tabs:

- Operations → Packages

- Products → Product Packaging’s

Enabling these unlocks full access to the packaging management features.

You can navigate to the module’s Settings menu to gain access to the packaging platform. You need to enable the Operations tab’s Packages option and the Products tab’s Product Packaging’s option, as seen in the screenshot below.

In this case, the options for Packages and Product Packagings serve different purposes. Packs of various products can be defined using the Packages option. On the other hand, product packaging will enable you to package various amounts of the same item. Let’s examine these choices in more detail.

Types of Packaging in SAS Inventory

SAS Inventory supports two primary packaging methods:

1. Packages

Packages in SAS Inventory are used to group different products into a single unit for delivery or storage. This is particularly helpful when shipping multiple items to the same location or when handling bundled products (like gift sets or kits).

📦 How to Use the “Packages” Feature Effectively:

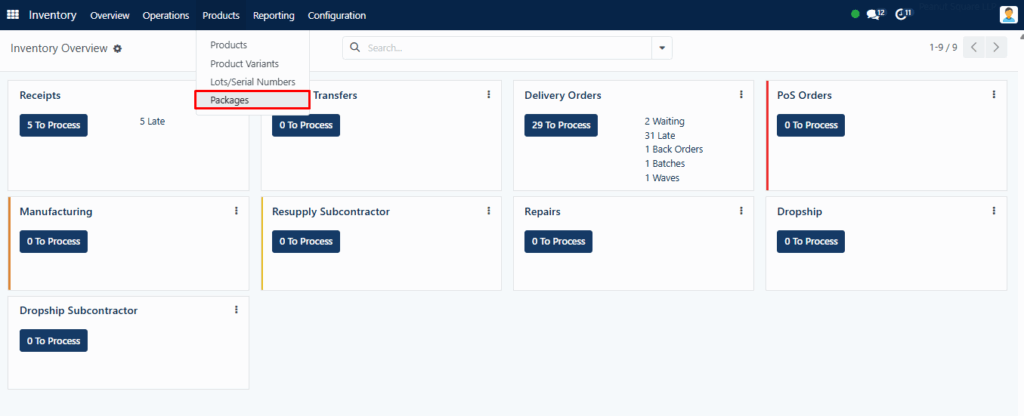

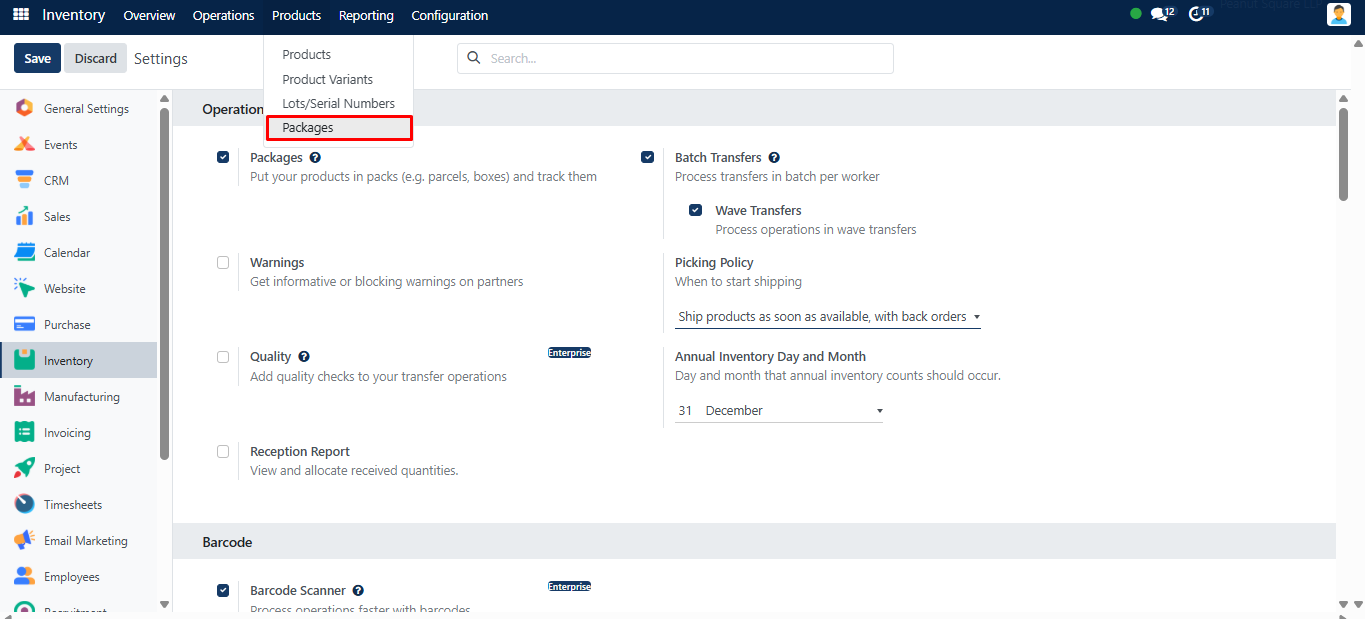

Once enabled from Settings → Operations → Packages, a new menu item appears under Products → Packages.

Steps to create a package:

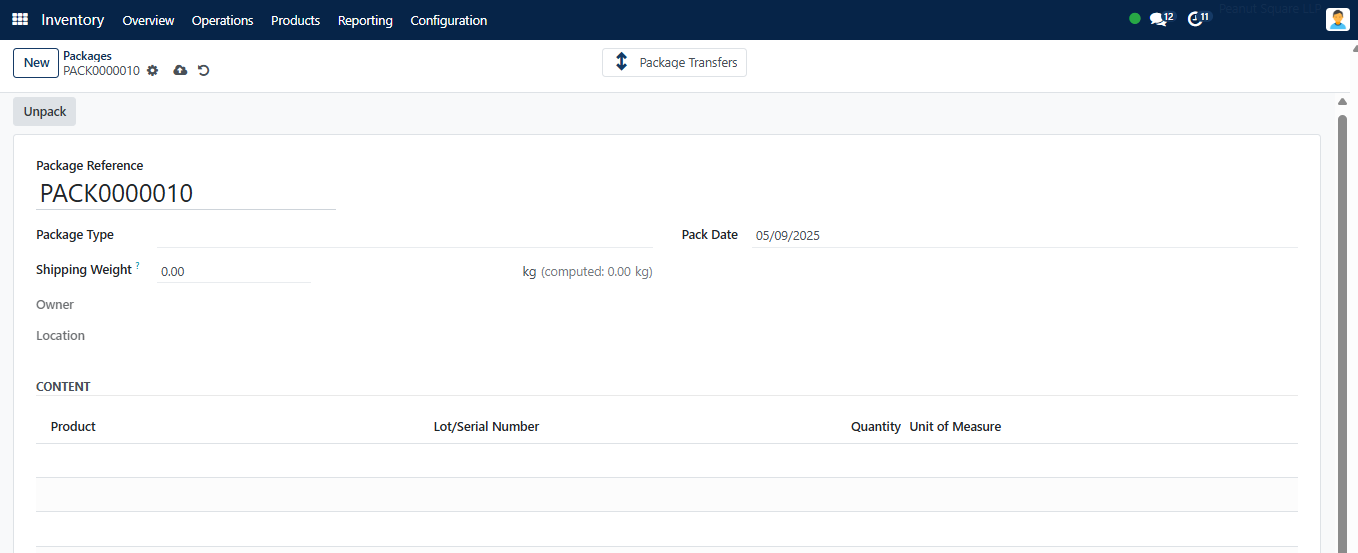

- Click New to open the form view.

- Enter a Package Reference—a unique identifier.

- Select a Package Type from your predefined options.

- Add details like:

- Shipping Weight

- Owner

- Location

- Pack Date

- Under the Content tab, list the products:

- Product Name

- Quantity

- Unit of Measure

- Lot/Serial Number (if applicable)

You can construct packs of different products with the aid of the Packages function. With this function, several products can be combined into a pack. The Packages sub-menu is located under the Products menu after you enable the Packages option from the Settings menu. Packages that have already been produced are visible from this menu.

You can click the New button to create a new bundle. You will see a new form view as a result, as indicated below.

The provided field will have access to the Package Reference. From the available options, choose a Package Type that meets your needs. You can enter the package’s entire weight in the Shipping Weight section. You can enter the package’s Owner, and Location in the corresponding fields. The form will have the Pack Date available. The products included in this package are displayed in the Content tab. Once you use this package for stock movement, you may see the Product information, Lot/Serial Number, Quantity, and Unit of Measure.

🚚 On Delivery Orders:

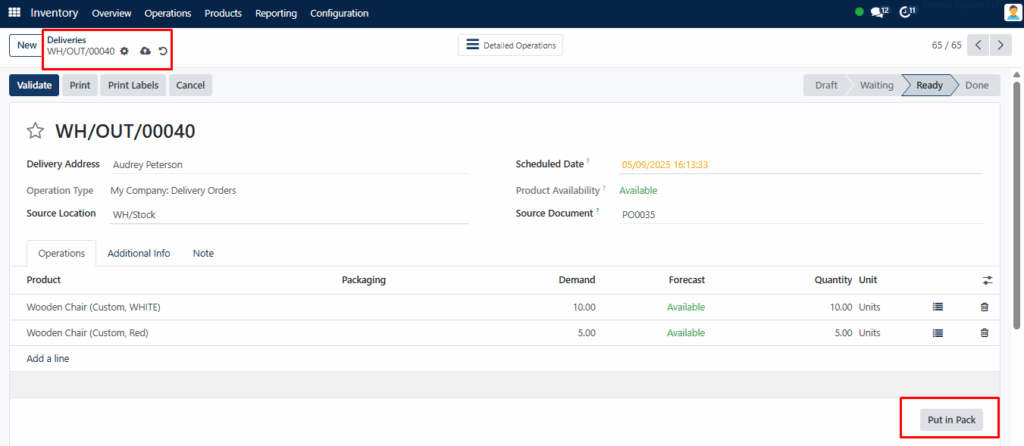

As you can see below, you will have the ability to pack numerous products together when confirming a delivery order.

During delivery operations, the Put in Pack button (under the Operations tab) allows you to group items in the shipping order into one physical package.

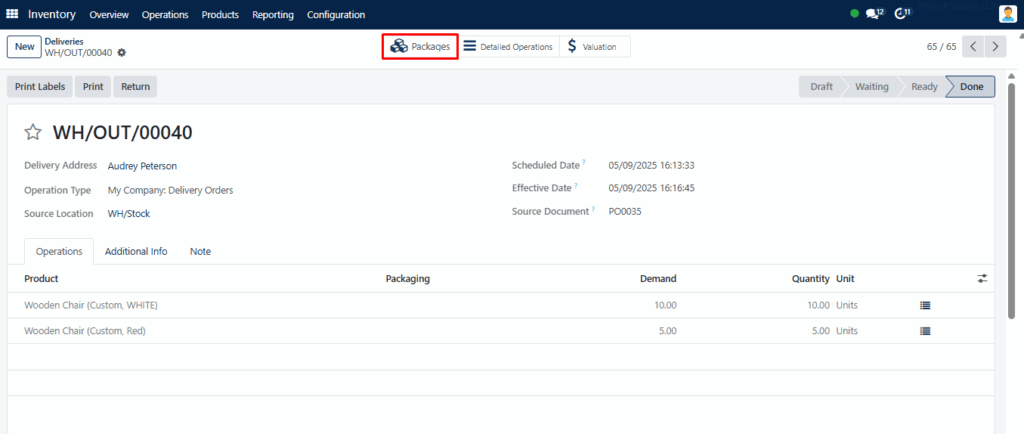

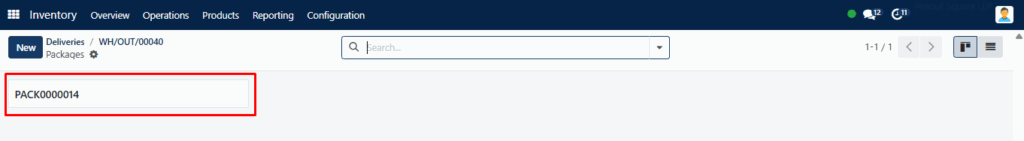

To view the package for the relevant delivery order, press the Packages smart button.

The Inventory module’s Packages menu will automatically record this package.

2. Product Packaging

Product Packaging is intended for packing different quantities of the same product, such as:

- 1 bottle

- 6-pack

- 12-pack

- Bulk box of 24 units

This setup is helpful for companies that sell in both retail and wholesale formats.

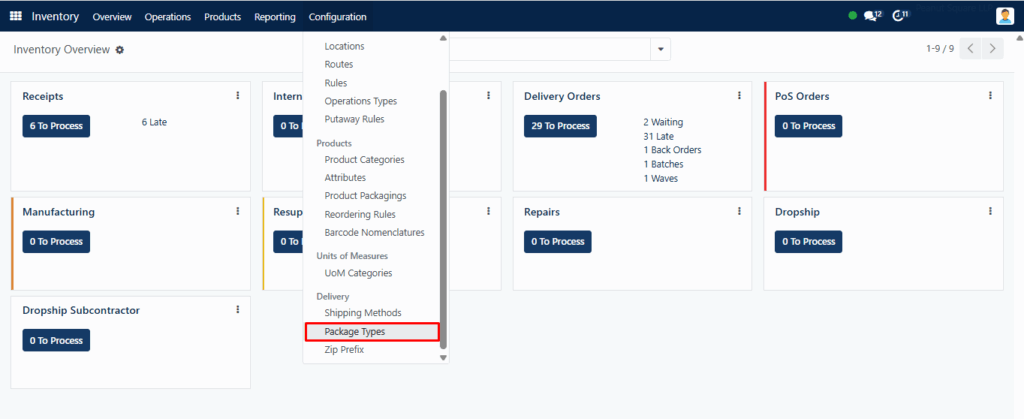

Configuring Package Types

To create different package types for various logistical needs:

- Navigate to Configuration → Package Types.

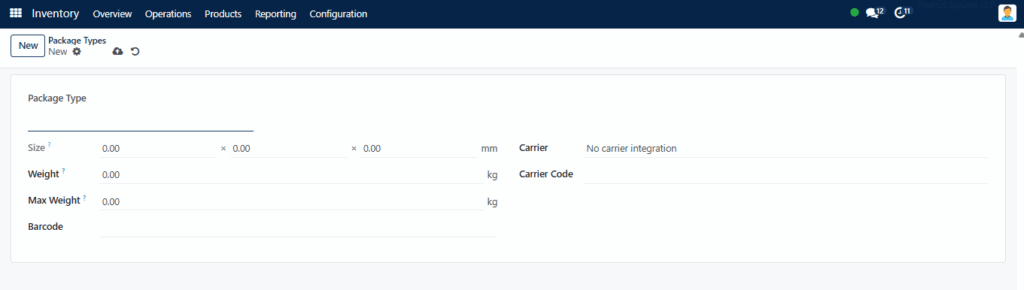

- Click New and fill in:

- Name

- Dimensions (Height, Width, Length)

- Weight & Max Weight

- Carrier, Carrier Code

- Barcode

- Company

- (Optional) Enable Storage Categories from Settings to define category capacity.

This helps optimize warehouse storage and shipment handling.

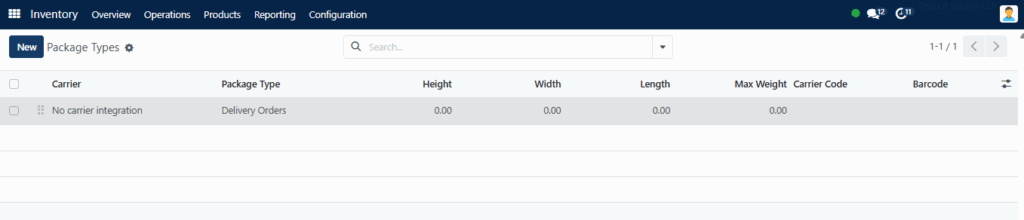

The carrier, package type, height, width, length, maximum weight, and carrier code are all displayed in this list view. Create a new package type by using the New button.

Add the Package Type name and the Size information in the designated field. You can enter the package type’s weight, the maximum weight that can be shipped in it, the barcode, the carrier, and the carrier code in the respective areas.

Key Benefits of Product Packaging in SAS Inventory

✅ Damage Prevention: Proper packaging safeguards products during transit.

✅ Operational Efficiency: Packages reduce handling time and errors.

✅ Barcode Integration: Quickly scan and track packaging with the Barcode app.

✅ Custom Configuration: Tailor packaging to product types and logistics strategies.

✅ Improved Reporting: Better visibility into packaging data for inventory analysis.

Best Practices for Using Packaging Effectively

- Always define package types before starting to package products.

- Use barcodes for high-volume operations to simplify scanning and tracking.

- Link packages to delivery orders to maintain full traceability.

- Regularly update package dimensions and weights to stay aligned with carrier regulations.